Our mission – our promise:

Build everywhere!

Aside from climate change, it is the biggest current and future global crisis affecting billions of people and threatening social peace all over the world: the housing crisis! The world’s population is growing steadily. Affordable housing is becoming increasingly scarce all over the world. Especially in developing and emerging countries, access to it is difficult or impossible. In addition, the problem is exacerbated by the shortage of skilled workers in the construction industry. Our ambitious goal is to make a significant contribution to solving the challenge of the worldwide housing and infrastructure deficits together with our customers and partners. Because our name alone holds the promise: NEULANDT aims to develop new land in a way that transforms it into socially, economically, and ecologically valuable land. Every day. In every place. The basis for this is our mobile field factory N3P for the industrial mass production of precast concrete elements on site. The N3P makes precast concrete parts available at any location. Without time-consuming transport. Because here, the elements are efficiently poured, shuttered, and strengthened directly at the construction site, saving you time and money.

The meaning of home is universal! Let‘s create living space together. Everywhere in the world. Sustainably. Economically. Qualitatively.

Home

/həʊm/

noun

- home, housing in which someone is at home and feels comfortable

- the place where one lives permanently, especially as a member of a family or household

Discover new possibilities with our N3P portable precast plant

Transform today’s world into tomorrow’s living space!

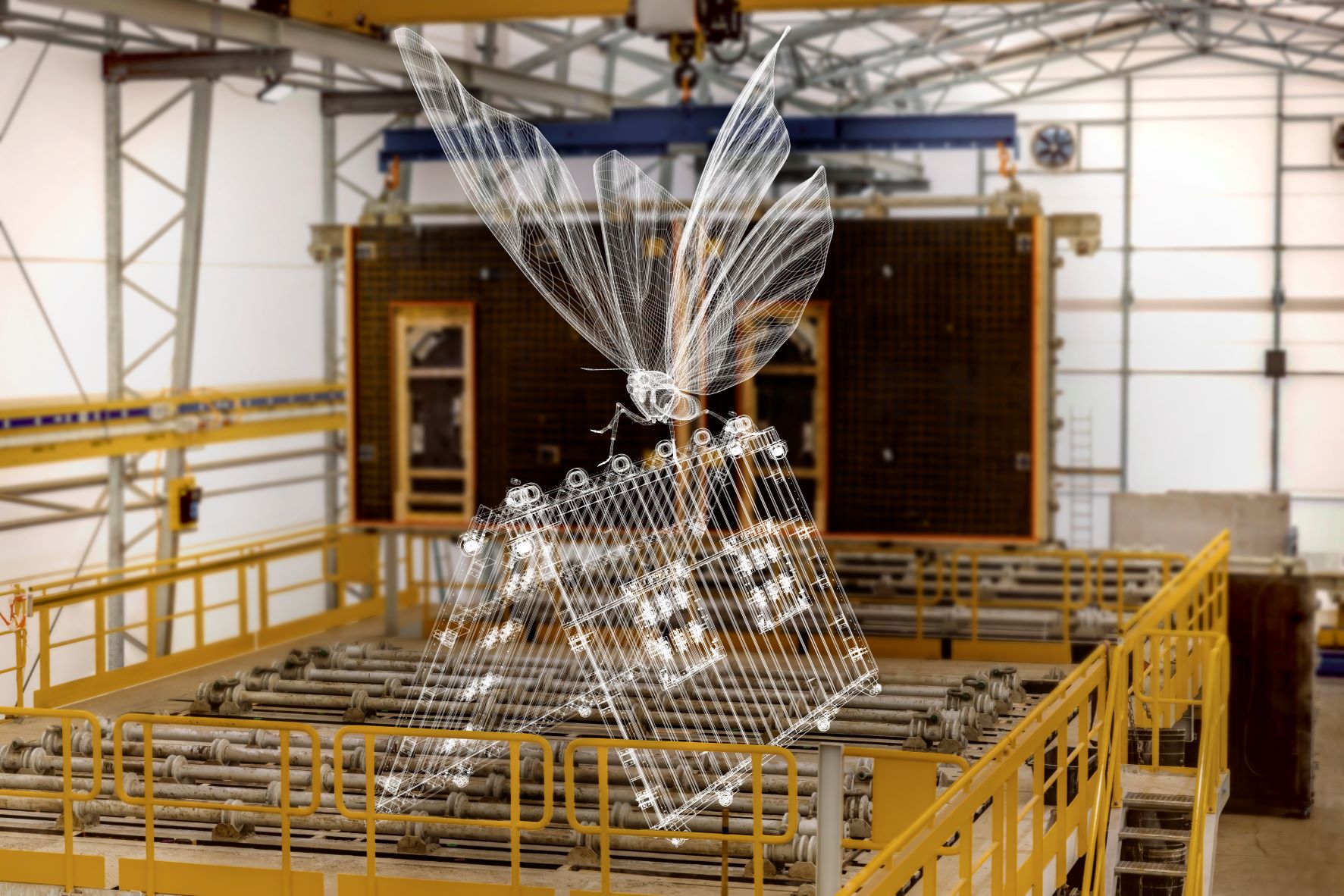

The world’s population is growing. How can we create affordable housing for everyone? With NEULANDT 3P, the Portable Precast Plant (N3P) for the industrialised production of concrete precast elements – worldwide. We have developed the NEULANDT 3P (N3P) as a portable onsite plant to be used for the industrial mass production of precast concrete elements. The concept revolves around innovative butterfly formwork technology, which is based on hinged steel formwork. This technology enables wall and ceiling elements (including box-outs for openings, reinforcement and built-in technical fittings) to be prepared ergonomically in a horizontal position, before the concrete is poured in a vertical position in the battery. Used in combination with our planning and service tools, the N3P results in an efficient production process that – protected from the environment – enables a constantly high level of quality. The integrated infrastructure realises a simple ‘plug and play’ method of construction.

A glance at the N3P

Packaging:

40 standard containers (40 foot)

Area of plant site:

2–3 hectares

Footprint of production:

70 m long, 15 m wide, 12 m high

Integrated infrastructure

- Two integrated 12.5-tonne cranes

- Technical infrastructure for electricity

and water connections

Factory assembly time

4–6 weeks

What does the butterfly mean?

The N3P is based on the innovative butterfly technology. This is a system that uses hinged steel formwork in the form of butterfly wings. For this reason, the technology is also referred to as “Butterfly Technology”.

Construction method with a future: precast concrete production onsite.

NEULANDT is your digitalisation and industrialisation partner to assist with your sustainable construction of your quarter. With our N3P portable precast plant, we make the creation of affordable living space possible even in the parts of the world where the challenges to urban planning and access to housing are greatest. Besides state-of-the-art engineering, our plant and services rely on all aspects of digitalisation and industrialisation for the most efficient and sustainable project delivery. Our ambition is to support the entire construction process, including all stakeholders, engineers, urban planners, concrete plant owners, construction companies, investors and governments, to ensure broad-based home ownership. To this end, our portfolio also includes aspects of design, project management, logistics, operations, financing, recycling and capacity building. NEULANDT’s ambition is to be your partner in sustainable construction. And our software solutions support construction planning optimised to conserve raw materials and which is implemented through our optimised precast technology. This innovative, hollistic concept allows for maximum local content in terms of planning, raw materials, production and construction.

Your portable precast plant from the leading turnkey mobile plant provider:

Infrastructures of all kinds are needed worldwide faster than they can be built. Industrialisation is the answer to this challenge. With rising transport costs and the need for sustainable solutions, it is economically and qualitatively crucial to fully exploit the potential of prefabrication. This construction method offers cost efficiency, quality, and fast execution and uses durable materials for long-lasting infrastructures.

NEULANDT’s mobile field factory N3P combines many benefits. In addition to the production of precast concrete elements, it also promotes the training of local employees. And it enables all stakeholders to exchange knowledge about the industrialisation of the construction industry and the implementation of large construction projects.

Faster, more efficient construction:

With the N3P 1,000 m² of precast elements (1,000 m² of reinforced concrete wall elements) can be produced per day directly at the construction site.

Regional value creation:

Many local employees are hired and trained by the NEULANDT team. This brings work, income, knowledge transfer and high value creation to the people in the region.

Local support:

Investors receive extensive support from us. We advise and help with financing, planning and engineering offices, installation, and supplying materials.

Forward-looking cooperation:

Actors and interest groups in the construction sector are given initial insights, education and support on the path to industrialisation. This has the aim of working together, especially on large-scale projects in the social and economic sectors.

If precast concrete elements are produced directly at the construction site, this saves time, costs, logistics, the need for transport and CO2. Building projects can be realised more sustainably, economically and quickly while maintaining the same high quality. This also opens up access to the realisation of new living spaces for developing and emerging countries as well as remote regions all over the world.

Learn more about N3P

What is the biggest crisis affecting billions of people?

“N3P” – what does it stand for and what does it mean?

News

How NEULANDT helps developers and construction companies in minimizing risks and costs!

“Increasing efficiency, saving costs and [...]

ARCHIBAT 2023

Next step towards the industrialisation of the construction sector [...]

Opening of the first portable precast plant for the prefabrication of precast elements

Premiere: Opening of the first portable precast plant (N3P) [...]