Precast Plant Service – our services so you can build everywhere.

Throughout the world, cities are growing. More and more people need more and more living space. Especially in developing countries, settlements and cities are growing rapidly. Classic construction and manufacturing processes cannot absorb these developments. With the innovative mobile field factory N3P, NEULANDT offers the construction of the future in every part of the world. Because that is our claim, our goal, and our promise: BUILD EVERYWHERE. The N3P enables the production of precast concrete elements at any location, directly on site at the construction site. This is not only faster, more sustainable, and more economical. The production also involves local labour. This brings know-how, jobs, and a lot of added value to the region.

With our comprehensive Precast Plant Service, we make your field factory even more productive, the processes even more manageable, and the costs even more predicable.

Precast Plant Service for the mobile concrete part production of the future.

The N3P has been designed to be constructed and operated on the project site. The N3P takes up only 2 – 3 hectares and comprises the following areas:

- NEULANDT 3P

- Storage area for curing the precast concrete elements

- Container for tools and spare parts

- Concrete mixing station and raw materials storage

- Houses under construction

- Completed houses

- Occupied houses

The plus with the portable precast plant: The NEULANDT Precast Plant Service.

NEULANDT provides a comprehensive package of equipment, know-how, and services that enables our partners to build anywhere in the world. In other words, we provide more than just equipment. We also provide the necessary expertise and all associated services consolidated in our Precast Plant Service. This clearly demonstrates NEULANDTS´s holistic, integrated approach. Indeed, it is this very philosophy that enables you to build everywhere with the NEULANDT portable precast plant.

TRAINING: everything hand in hand until commissioning.

Our experienced team of trainers coaches our partners’ local staff until they have sufficient knowledge and skills to operate the plant. Our team of trainers is directly on site for several months, wherever this may be in the world. During this time, we train:

- Skilled and unskilled local workers to operate the N3P equipment in in achieving the desired shift-model.

- Skilled construction workers to build houses from precast elements.

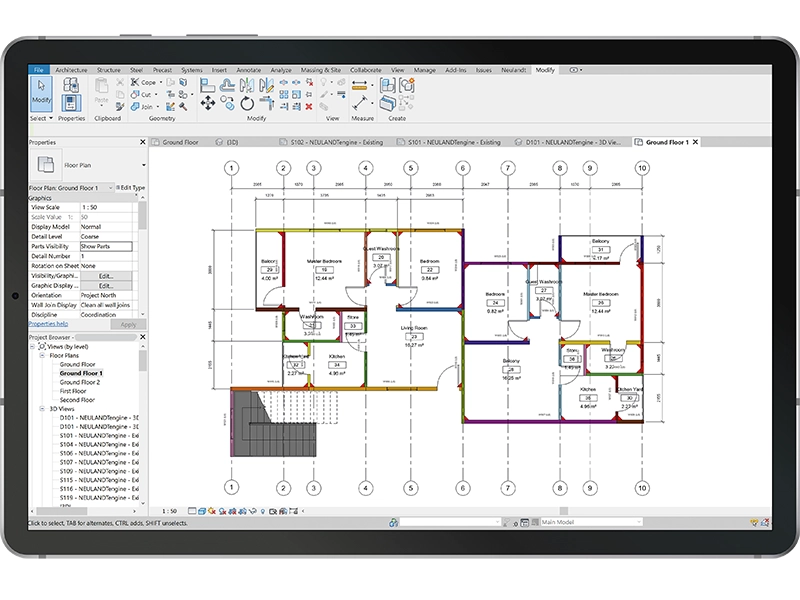

- Local engineers and architects in precast concrete construction technology, optimal building design, and our high-performance software.

SOFTWARE: how plans become precast concrete elements.

Our advanced software solutions are compatible with the most common CAD programs. It not only ‘translates’ existing construction plans into precast concrete elements, but also performs a precise analysis of the commercial aspects.

Our software solutions provide data for preparing quotations, and covers the commercial management of the project from A to Z.

SUPPORT: at your side from the very beginning.

It is important for us to also provide partners with support before the investment decision is made.

We support them with the preparation of initial business models, case studies, the best financing structure, and certification in line with the national construction standards.

Our Precast Plant Service as an accompanying service over several project phases.

Our Precast Plant Service for your projects all over the world.

Financial Service

We support you to obtain financing of your N3P portable precast plant. We assist you in the process of qualifying your financing. We participate in the development of the business case.

Design Service

The design of your structure is part of the key to success. We train your staff to perfectly match the structure design to the plant capacity. And show you which plant module is the best solution for your project.

Field Service

Many trades come together in the N3P portable precast plant. This makes managing the supply chain critical. That’s why we send the NEULANDT team to your construction site to assemble the plant. We also support and train the plant manager, who has to coordinate all the trades. In addition, we implement a production control centre software for optimal production planning and documentation, which also covers quality assurance.

Logistic Service

With our plant logistics, we support you with the entire plant planning. In doing so, we create a model plant, so to speak, which is then custom adapted to your project in terms of warehouse size, machinery fleet, and so on. If required, we can also arrange partners for you to coordinate the machines and systems with the N3P used.

Precast Plant Service Software

From concept to creation: Capacity planning in the Precast Plant Service.

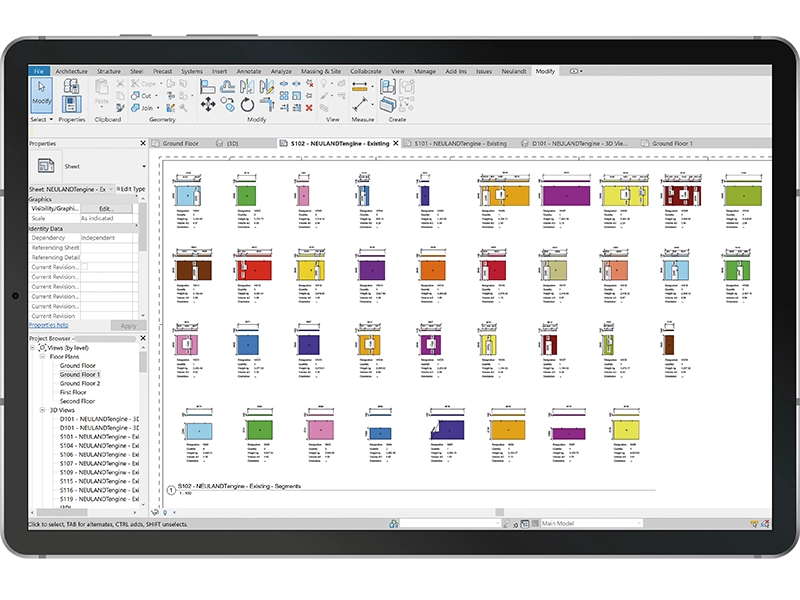

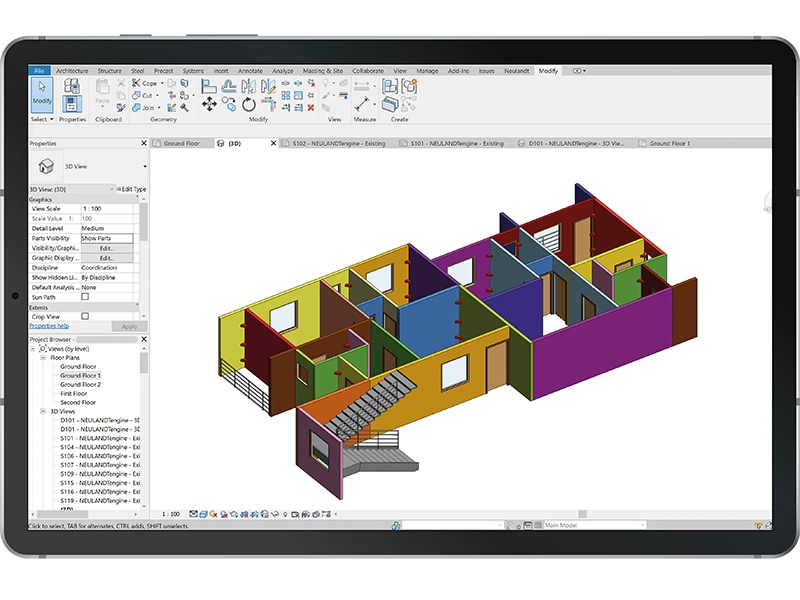

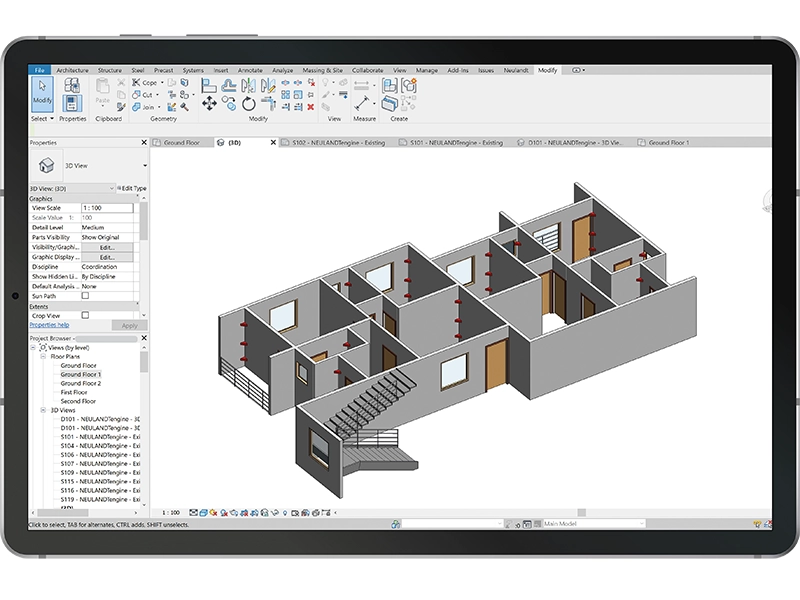

Capacity planning is carried out in our Precast Plant Service with two innovative software solutions. NEULANDTengine and NEULANDTcalc. After users have been trained, both systems can be used independently by the partner for the economic and technical analysis of projects. NEULANDTengine and NEULANDTcalc elevate the N3P to the peak of productivity.

This unique software applications optimise production processes for the specific needs of each construction project to ensure maximum efficiency over the long-term.

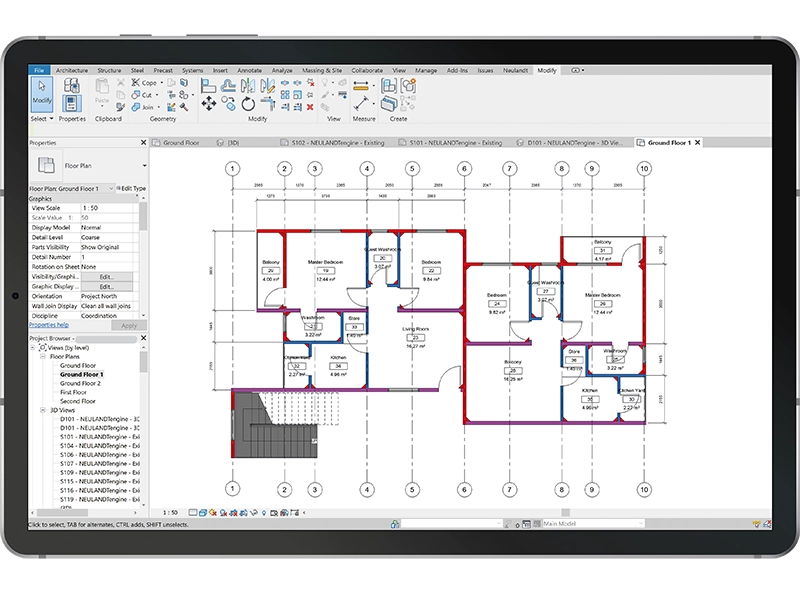

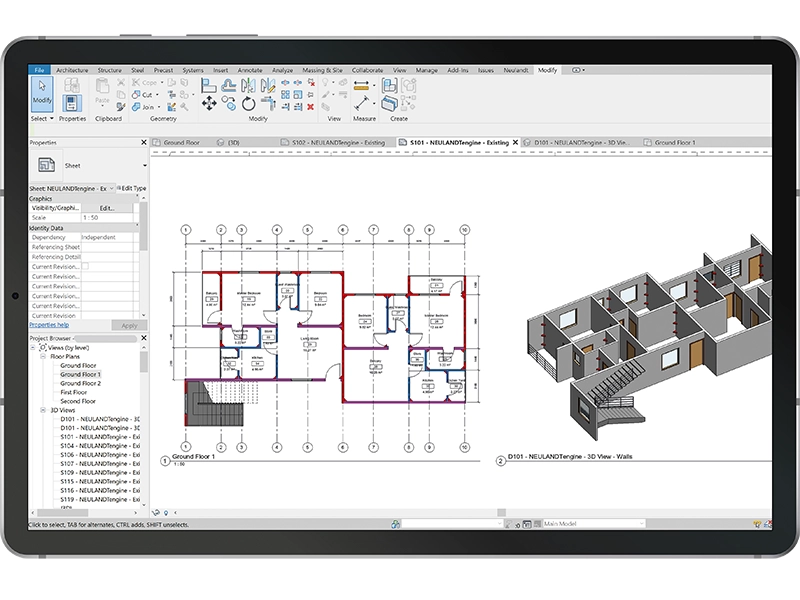

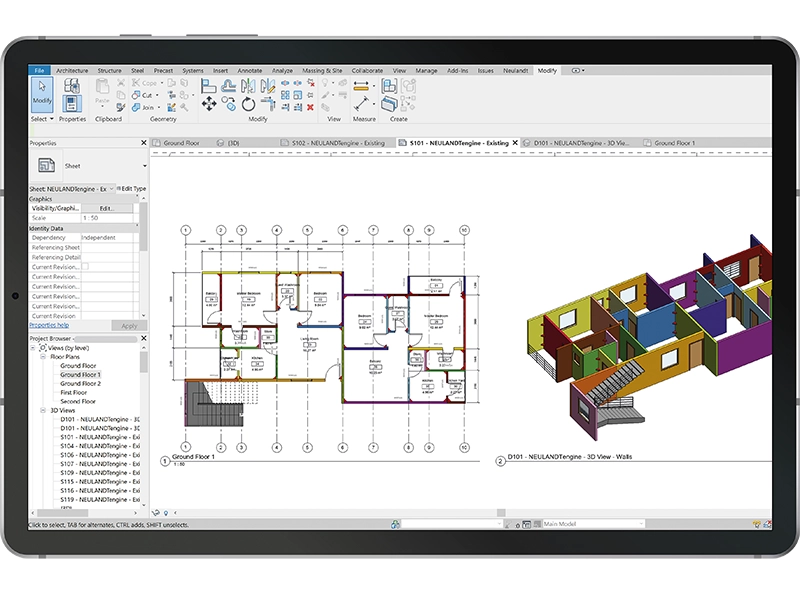

NEULANDTengine: the optimisation software in our Precast Plant Service.

Maximum efficiency of the N3P due to optimised segmentation and production process planning of the desired development

NEULANDTengine partitions the buildings based on predefined production criteria of the plant, such as size or weight. For this purpose, a building plan is entered into NEULANDTengine. From this, the software provides the optimal segmentation. This means that the most efficient occupancy of the butterfly formwork is determined in order to achieve the best possible utilisation during concreting. The segmentation is mapped in production units (PU) per day: PU here means the most sensible logical occupancy that can be duplicated.

Your planned structure will be analysed and segmented and any potential for optimisation will be identified. We also provide support in the selection of fasteners and in the development of the structural system. This is also where the optimal use of materials is defined in order to subsequently obtain plannable costs. After all, one of the cost drivers in precast construction is the concrete and cement costs. Together with the partner, we develop a suitable formula that is optimally matched to the requirements. Requirements of a static nature, but also the consideration of local availability, are essential here to ensure economic production.

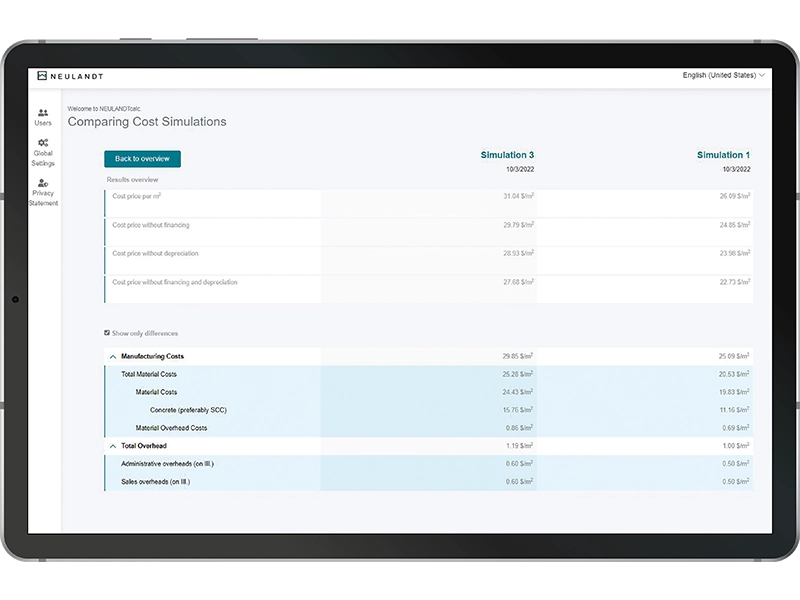

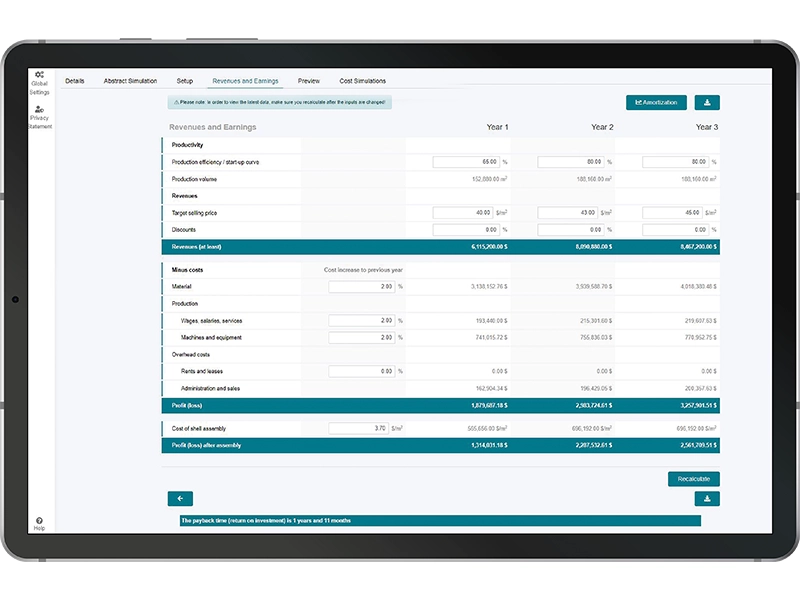

NEULANDTcalc: The calculation software in our Precast Plant Service.

Cost simulation software for the precise calculation of the partners’s construction plans

In NEULANDTcalc, the information from NEULANDT engine is then presented concisely. You can therefore create different projects, calculate the business case and your costs. This gives you full cost transparency and ability to plan.

This tool enables you to calculate the whole construction project using data provided by NEULANDTengine. You know from the start how much the shell construction of a particular building will cost from the outset. You can therefore compare the cost of N3P construction with other construction methods.

Scalable and customisable: N3P in our NEULAND Precast Plant Service.

You can start with a small version of the N3P, which can then be expanded in line with your requirements and investment capabilities. Like every other industrialised facility, N3P works most efficiently and profitably when used to full capacity. This means that the building structure you decide on, expressing your individual design, needs to be aligned with the production capabilities of the plant. We recommend a grid-based design for buildings wherever possible. Try to standardise your buildings as much as you can. In other words, use the same length of walls, and the same dimension of doors, windows and wall openings to reduce the number of different types of elements.