Our solution for the onsite production of precast concrete!

In the past, concrete was commonly cast directly on the construction site. Then, over the past few decades, constructors started to replace onsite casting with precast concrete from the factory. Building with precast concrete elements has the advantage of making construction projects more economic, faster, and less dependent on weather conditions. Onsite production brings even more benefits. It combines the advantages of building with precast concrete elements, such as standardised high quality at lower costs, with the speed and cost advantages of the mobile field factory. Employ the N3P mobile field factory from NEULANDT to cast, form, and cure precast concrete parts directly at the construction site. As a result, the required parts do not have to be transported across the country, but are directly onsite, saving time, costs, and CO2. The N3P combines the best of both worlds: the advantages of an industrialised plant with minimal transportation costs owing to onsite production.

Precast concrete from N3P: unique technology for standardised buildings.

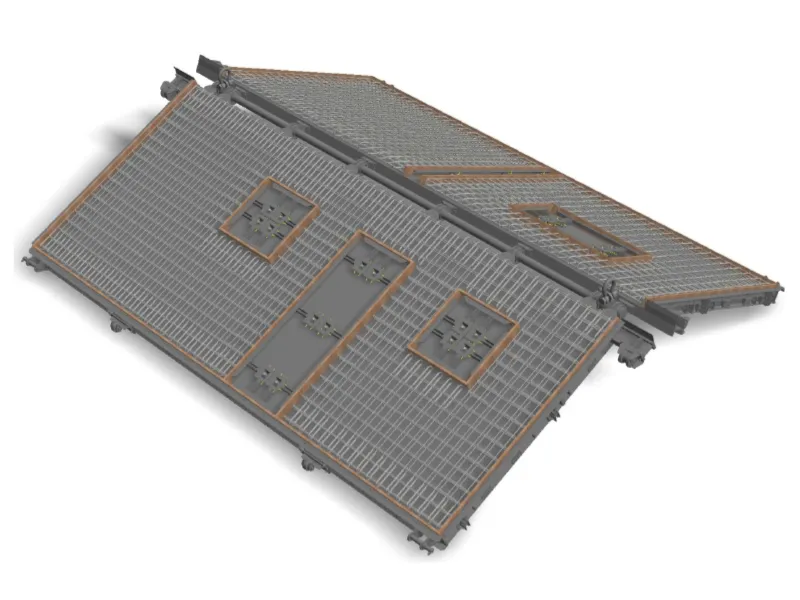

N3P stands for NEULANDT Portable Precast Plant and describes our mobile, modular production facility for precast concrete. What makes the N3P so unique? The technology! The plant is based on our butterfly technology, which allows both horizontal preparation and vertical pouring – two traditional, tried-and-trusted precast production techniques.

The butterfly technology separates preparation from pouring, resulting in better performance and higher output. Carrying out the preparatory steps on horizontal moulds is much easier and more ergonomic. In addition, vertical pouring ensures the desired surface finish on all sides of the concrete panel. Besides being mobile, the plant has a modular design, allowing contractors to adjust production capacities to the project size.

Based on an exclusive NEULANDT GmbH licence, BT Innovation distributes the patented butterfly formwork and battery only for stationary applications.

Produce precast concrete elements easier, faster and more economically onsite.

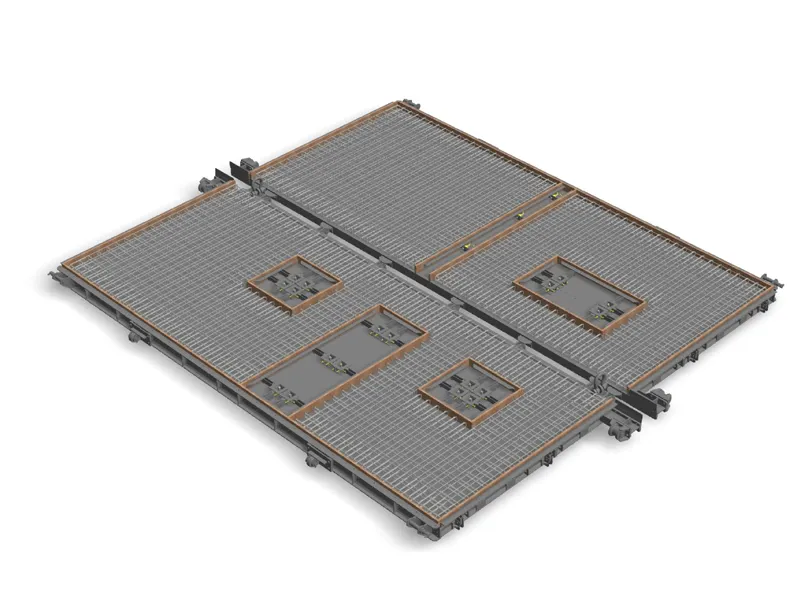

The core of the N3P system is the innovative butterfly technology inside the portable precast plant. The high-performance battery is equipped with removable, folding, and double-sided steel butterfly formworks. A butterfly formwork consists of two formwork panels held together by a hinged joint. The N3P has been designed with top performance and maximum productivity in mind. Our solution combines the advantages of preparing the precast concrete elements in a flat position and pouring the concrete into vertical formworks.

More about the production process

How can so many elements be produced in such a short time?

Six steps to the optimum precast concrete element onsite:

Step 1: Prepare

- Tie in the reinforcing cages on the rebar preparation tables.

Step 2: Assemble and position

- Assemble stop-end and box-out formworks.

- Position ready-made rebar cages on the butterfly.

- Assemble inlays for electrical cables and plumbing.

Step 3: Pour

- Lift the prepared butterfly into the pouring chamber of the duplex battery using the crane.

- Repeat lifting process until the pouring chamber contains 7 butterflies.

- Close the pouring chamber by pushing the end shutter wall towards the centre of the pouring chamber.

- Place form ties into secure position.

- Pour the concrete in layers, using a concrete pump and rotary distributor.

Step 4: Open formworks

- Rest precast elements for another 4 hours.

- Strip box-outs and stop-end formworks.

- Separate panel from butterflies using a crane.

Step 5: Initial curing

- After approx. 4 hours of curing, lift out the precast elements and position them together at the initial curing area using the butterfly.

Step 6: Final curing

- Transport the panels to the final curing yard.

- Allow the panels to cure until the required strength for shell assembly is achieved.

- Transport from the curing yard to the desired location for assembly.