The solution to creating affordable living space. Everywhere in the world.

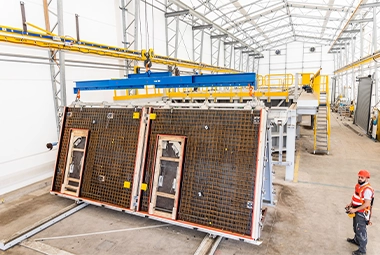

The NEULANDT portable precast plant N3P brings you sustainable solutions to overcome the unique challenges of the future. It has been designed for the economic manufacturing of precast concrete elements at the actual construction site, ensuring the highest levels of productivity and structural quality. With N3P, we have created a portable precast plant for the industrialised mass production of precast concrete elements, which realises fast and reliable construction. At the heart of it all is the innovative butterfly technology based on foldable steel moulds. The flexible butterfly enables ergonomic and horizontal preparation of wall and ceiling elements, including recesses for openings, reinforcement and built-in parts of the technical building equipment, and their final vertical concreting in a duplex-battery. The mobile N3P production plant in combination with our planning services creates an efficiently timed production process, which allows for consistently high quality and a simple plug & play construction method thanks to the integrated infrastructure.

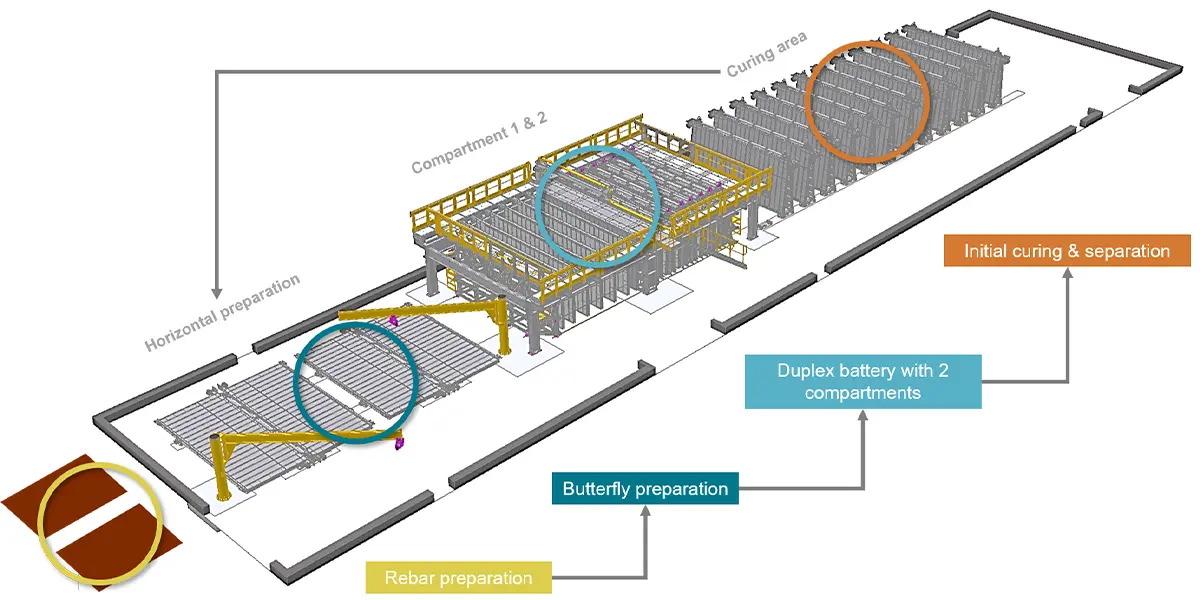

How production runs with a mobile field factory:

With the portable precast plant N3P, NEULANDT supports the industrialisation of construction sites. The concreting, striking, and curing of the precast concrete elements is performed directly onsite using our innovative butterfly technology, which combines the advantages of both horizontal preparation and vertical pouring. In the production process with the N3P mobile precast plant, the reinforcement cages are prepared first. Once preparation is completed the cages are transported into the plant were they are joined with the butterfly. The butterfly, which closes its wings when lifted, is thereafter placed in the pouring compartment of the duplex-battery. The concrete is poured in after the battery system has been closed. Up to seven butterflies or 14 chambers can be filled per hour. After four hours, the butterflies with the young prefabricated parts enter the initial curing area. Once the precast elements have reached the required strength for lifting, they are separated from the butterfly and loaded on the transportation pallets for relocation to final curing yard. Once the butterfly is cleaned it will be returned to the butterfly preparation station where the process starts all over again.

Production and construction: precast concrete parts onsite with N3P.

The N3P portable precast plant from NEULANDT offers you a unique technology with which you can realise up to 1,000 housing units on site in the shortest possible time. It is made possible by the innovative butterfly technology.